-

-

Notifications

You must be signed in to change notification settings - Fork 19.3k

New issue

Have a question about this project? Sign up for a free GitHub account to open an issue and contact its maintainers and the community.

By clicking “Sign up for GitHub”, you agree to our terms of service and privacy statement. We’ll occasionally send you account related emails.

Already on GitHub? Sign in to your account

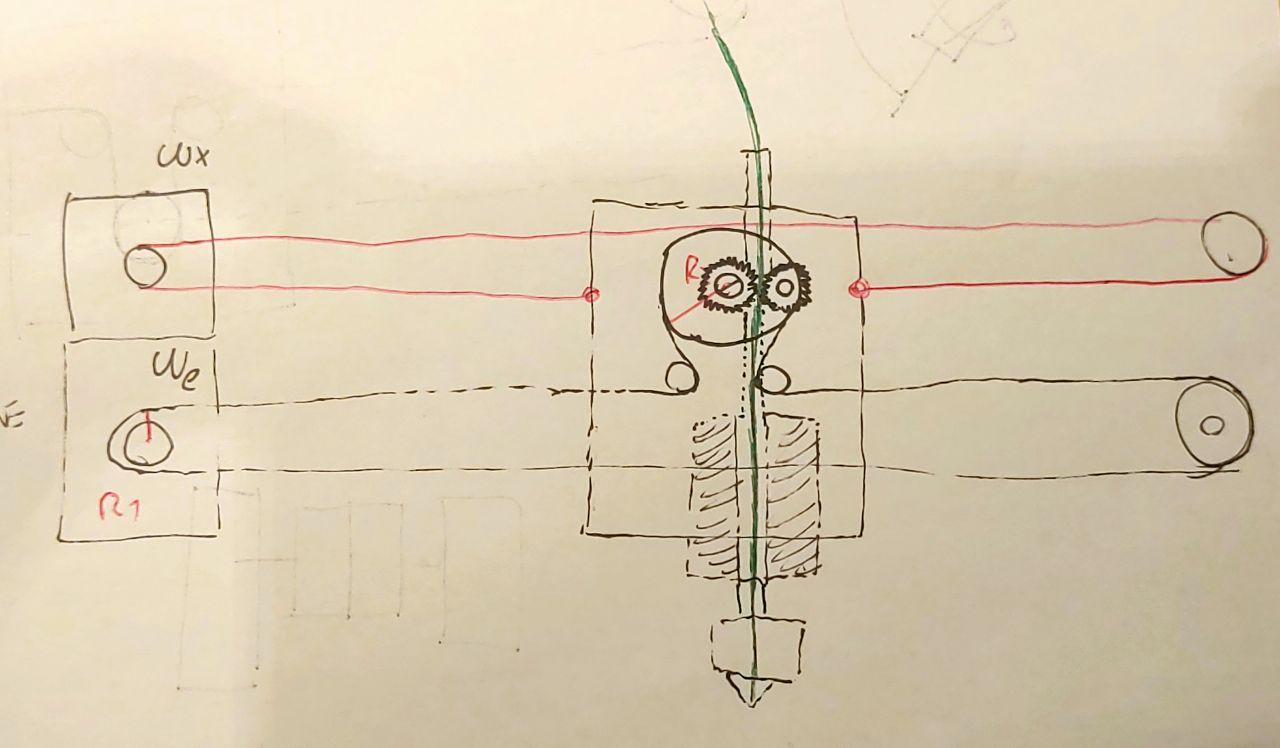

[FR] Remote extruder kinematics #17995

Comments

|

Ouch... I can feel the pains of poor planner... And hunders, hundreds of hours spent making it work... How do you plan on integrating it with LA and S-Curve? |

|

Shouldn't the RE motor motion just be X+E if the motors are mounted like the attached picture and E-X if the X and RE motor are coaxial and facing each other? |

|

Without corrections - yes, in theory it's no different from CoreXY. In reality? At high speeds? I suspect extrusion will suffer after 70-80mm/s even without LA and Scurve. |

|

For cartesian gantry style printers, like prusa, ender 3 and many others,

the XZ carriage is already holding the weight of the extruder motor, the

advantage of this solution is having a direct drive extruder without having

the X carriage carrying the extruder motor around...

Il gio 14 mag 2020, 18:07 EvilGremlin <[email protected]> ha scritto:

… Without corrections - yes, in theory it's no different from CoreXY. In

reality? At high speeds? I suspect extrusion will suffer after 70-80mm/s

even without LA and Scurve.

Though your idea doesn't make sense anyway. If you put it onto XY extruder

Z bed - it'll jsat make one axis twice heavier, thus it's a massive

downgrade. If you but it on XZ extruder Y bed - bed is still as heavy as

motor, thus it's just useless.

—

You are receiving this because you authored the thread.

Reply to this email directly, view it on GitHub

<#17995 (comment)>,

or unsubscribe

<https://github.com/notifications/unsubscribe-auth/AO46MYWTTSZK4MBL7UXPSPTRRQJM7ANCNFSM4NAZH6NA>

.

|

|

Yep, but it doesn't make bed any lighter, so this is no better than pancake with gearbox or belt |

|

Bed? The aim is to reduce the mass of a X carriage with a direct drive extruder assembly. |

|

What's the point reducing mass of only one axis? Your speeds and quality only as good as heaviest carriage. |

|

The point is to get at least one axis better. |

|

Yep, to an extent. Remember that while your light X carriage go up your bed become heavier and heavier... IMO, it's better to build proper rigid and heavy CoreXY and don't waste time on half measures. |

Description

What if we have the filament drive gear remotely driven by a timing belt, driven from a motor located on the X carriage? This should achieve no-backlash, directly-driven and lightweight extruders.

This "remote extruder" (RE) motor will have to compensate the X motor movement in a differential fashion.

Feature Workflow

Users who adopt this feature will have to specify the details of the kinematic chain in the config file.

I have the skills and commitment to build the hardware, compile and test the software but I have no knowledge of the internal Marlin structure and working principle to autonomously implement this feature.

Cheers by diglo from Italy.

The text was updated successfully, but these errors were encountered: